3D printed fabrics have been taking their place in the fashion industry in recent months, and for good reason. This innovative technology simplifies production, cuts down on waste, and frankly, is just so cool! But as amazing as 3D printing is now, remember that this is only the beginning.

The technology will undoubtedly be improved and developed in a way that will take the fashion industry even further. In fact, one designer, Bradley Rothenberg, is already working on it.

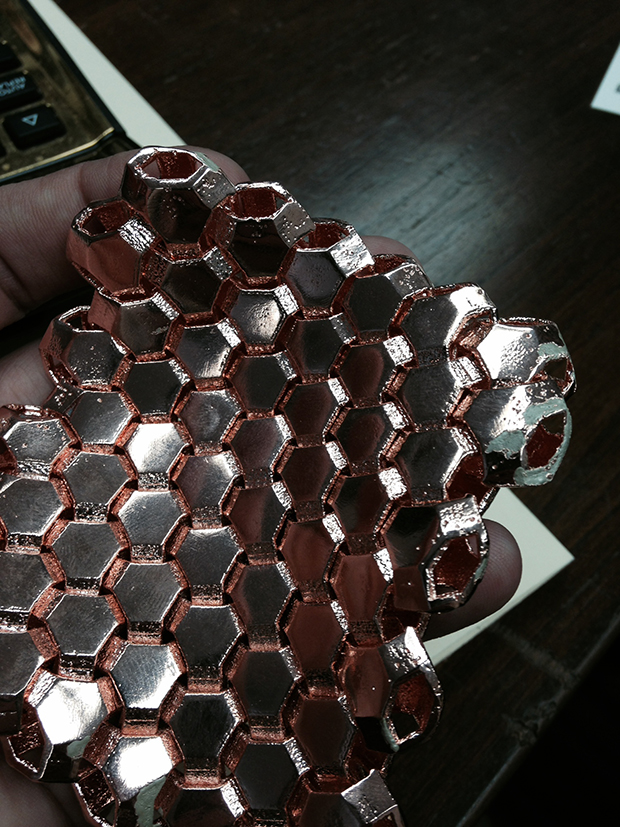

With a background in architecture, Rothenberg has developed an interesting new material he’s named “cellular textiles”- so named for the structure of the fabric.

Interlocking “cells” make up the material, which can differ in order to create variations in stretch, opacity, and flexibility. The resulting fabrics take on many different looks, from delicate lace to a heavy material reminiscent of chain maille. One sample even had copper plating, which added some serious glamour.

Rothenberg’s design studio is not limited to raw material however. His team is also working on creating garments that fit the wearer perfectly- and we mean perfectly!

According to Rothenberg,

We have been developing the technology to ‘grow’ these textiles around any 3D shape, so you can take a 3D scan of you and custom fit a sweater.

The idea of an easily accessible custom sizing sounds great, especially when it comes to pieces that are tricky to fit, such as jeans.

Want a look at Rothenberg’s work in action? Chances are you already have. For the 2014 Victoria’s Secret fashion show, the designer collaborated with Shapeway’s Duanne Scott to create a garment for Lindsay Ellingson. The resulting ensemble, which resembled an intricate, lacy snowflake pattern, was designed and printed to fit Ellingson perfectly.

What do you think of these “cellular” textiles? Would you ever wear them or use them in a collection?